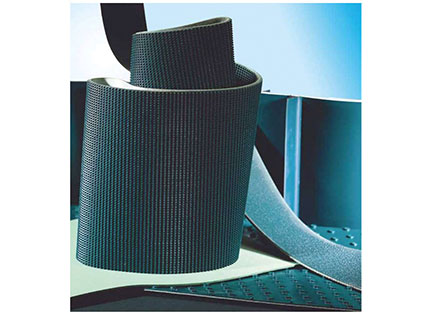

PVC PU NITTRA ® Conveyor Belts

The conveyor belts with a PVC covering are used in all types of industry and have rightfully become the most important part in the belt conveyor market.

The wide range and selection of NITTRA ® products allow to satisfy almost every need both for the industrial use and the food contact one.

In addition to PVC belts our range includes conveyor belts PU whose technical features allow a longer working life, a lower roll diameter as well as a higher resistance to temperature.

In order to ensure an efficient technical support in any working condition, our range includes also belts with particular coverings such as felt, rubber, Teflon, elastomer polyester, and silicone.

Thanks to the efficiency of our production facilities, we are in a position to apply guides, profiles or flexible side walls to almost every type of belts.

All this together with the expertise of our technical staff always allows our customers to find the most suitable solution and, at the same time, the cheapest one.

JOINTS SYSTEMS

The characteristics of the new materials and the steady technological progress in the applications of conveyor belts has led us to the development of various and specific joint systems.

The most common types are the following ones:

GROOVE JOINTS: they are characterized by high flexibility and guarantee the best performance at high speeds or against bending.

OVERLAPPED JOINTS: They are used for particular applications, as, for example, when a product tends to interpose between the drums and the belt, thus creating a stress in the junction area.

METAL JOINTS: they offer a very short belt replacement time because it can be mounted without any intervention on the structure of the assembly. They are available in different types and in galvanized steel or stainless steel.

SUBMERGED JOINTS: they are metallic joints where, junctiojunction, the belt covering material has been reconstructed.

They add both the flatness and the continuity of the conveying surface to the features of metal joints.

CURVED BELTS

One of the most significant applications of flexible fabrics is the one concerning the manufacture of curved conveyor belts.

In the curve, it is not possible to use rigid fabrics, since, to manufacture them, the cut is made along an arc of circumference and not in a straight line (parallel to the warp) as it happens for all the other types of belt. If for example the curve that must be achieved is 90 degrees, the material will have to be cut for a double angle (180 degrees), plus a further increase, necessary to obtain the overlapping of the joint and compensate the bending radii of the drums.

This last increase will vary depending on whether the drums are cylindrical or cone-shaped.

The conveyor belt made of two cone-shaped rollers is the most precise technical solution from the point of view of the pulling easiness and assembly.

In case cylindrical rollers of few tens millimeters of diameter, one of which will be the tensioner, the cutting is often successfully made by simply doubling the angle and adding only the extra piece necessary for the overlapping during sealing.