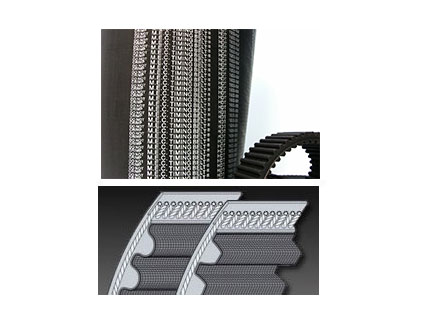

M.E.C. SYNCHRONOUS TIMING BELT® HTD® FOR INDUSTRIAL TRANSMISSION

HTD® MEANS HIGH TORQUE DRIVE

The synchronous HTD® belts are characterized by a new profile (rounded notched) which make it possible to transmit more power with the same pitch as traditional synchronous notched belts. To this the following advantages are added:

Reduction of noise and interference, increased resistance against notched being skipped and shearing stress, precise angular transmission and constant speed up to 50 mt/sec., low tensioning, excellent reliability, compact dimensions and moderate maintenance.

STD® MEANS HIGH TORQUE DRIVE

In addition to the advantage above indicated for HTD® belts the following advantages are added:

longer life thanks to the new profile edge and to a higher quality of the material used for the belt manufacture.

Temperature resistance between –40° and 100°C, resistance to atmospheric agents and moderately to the oil

No noise

Moderate maintenance

These belts permit the synchrony transmission, made in the past by means of chain, and therefore high power transmission with low revolution number.

CLASSIFICATION OF M.E.C. TIMING BELT® HTD® AND STD®

M.E.C. TIMING BELT® HTD® and STD® , identified by commercial names, are available in the following pitch diameters and standard widths.