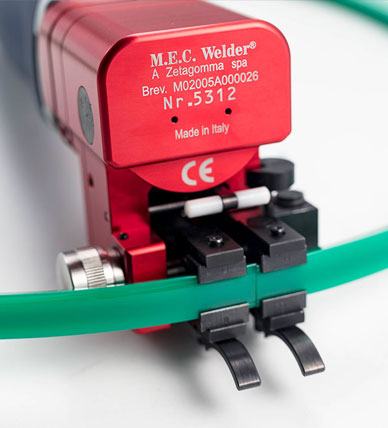

M.E.C. WELDER®

In a globalized economy where industrial goods are deeply affected by the competition from foreign cheap products, A Zeta Gomma, a leader in the field of rubber and polyurethane transmission belts, has carried out research to innovate its products in order to preserve the market success it has reached thanks to more than thirty years of activity.

The business has focused its efforts, above all, on the field of heat welding belts.

After obtaining a product quality that is unique in the market and is identified by the trademark MEC POLBELT ®, A ZETA GOMMA has tried to solve the age-old problem concerning the installation of the belt. The first-hand experience and the carried out studies have highlighted the fact that very often the reason why the heat- welding belts are used, that is easiness of use and rapidity of installation, is in reality distorted by the long technical times linked both to traditional tools and the operator’s poor practical experience.

Just to solve this problem A ZETA GOMMA has created MEC WELDER, a revolutionary tool meant to change forever the welding method of the heat-welding belts.

At present, the junction of these belts is made using traditional equipment that, through the superheating of a metal plate, allows the skilled operator to melt the sections of the belt to be welded.

Then they are left to cool in the proper blocking pliers.

Now all this is no longer necessary since MEC WELDER is an innovative welder containing inside a single instrument all the equipment that has been used so far.

It allows even unskilled operators to make fast and perfect junctions thus saving time and money.

MEC WELDER is an extremely good and efficient tool that uses a very easy principle: the friction principle.

The friction between the two sides of the belt generates the heat necessary to amalgamate the two sections so obtaining a faster and, at the same time, a more resistant welding.

This tool, patented by A ZETA GOMMA, has already proved to be very functional so allowing significant money savings.

If welding takes a skilled worker about 30 minutes with the traditional method, by using MEC WELDER anyone takes 6 minutes (estimated time), without any margin of error.

Moreover, with the MEC WELDER all types of MECPOLBET® belts can be welded: trapezoidal, round, crested and coated.

It is also possible to weld reinforced belts without removing either the ARAMID or the Kevlar surface of the two sections to be welded, with a further reduction of time and costs.