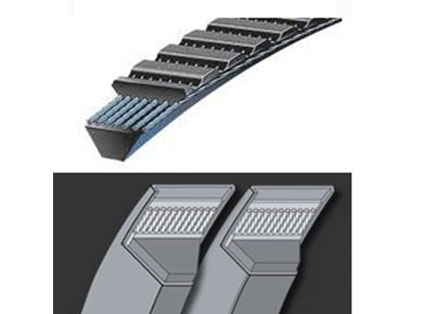

M.E.C. POLYFLEXOSIL BELT®

TO TRANSMIT MORE POWER IN LESS SPACE

Made of polyurethane and width insert of polyamide.

It is the ideal belt for machines tools and for all the machinery that need in a small space a high speed and a perfect and regular smoothness.

SPECIFICATIONS AND ADVANTAGES OF THE M.E.C. POLYFLEXSOSIL BELT®

- Exceptional abrasion resistance

- High modulus of compression

- High friction factor

- Better environmental agents resistance

- Stability of tension

- Perfect smoothness without vibration with high speed

- Reduction of the width of the pulleys

- High transmission ratio

- Long working life of the pulleys with small diameter

- Wide field of uses

- Reduction of the costs

THE PROPERTIES OF THE MATERIAL

The special mixture made of polyurethane has got special physical properties much better favorable than the most traditional materials usually used in the manufacturing of belts. As well as the excellent fatigue resistance and wear resistance, and the high friction factor, the polyurethane assures also an excellent ozone resistance, oxidation resistance, mineral oil resistance. The polyurethane enables also to improve the adhesion on the stands because the belt is obtained by pressure die casting.

THE SPECIAL RIBBING

The typical ribbing obtained by melting on the stands in polyamide assures a higher transverse stiffness, without reducing the longitudinal bending capacity.

The ribbing makes easier also the draining of the heat of the belt during the working.