M.E.C. GUM ®

The compositions, practical performance, low cost, hardness, elasticity and finish of the sheets and mats illustrated in the present catalog makes them ideal for almost typical applications.

When choosing a product grade it is very important to consider exposure to:

– natural agents (light, ozone etc.)

– chemical agents (oil, fats, fuel, acids, solvents, etc.)

– physical agents (high and low temperatures)

– mechanical agents (abrasive action, repeated stresses, heavy loads).

An inappropriate choice could lead to a rapid deterioration of the original characteristics.

ACTION OF NATURAL, CHEMICAL, PHYSICAL AND MECHANICAL AGENTS

The catalog lists conditions of use in relation to the agents defined above. If the foreseen use of a product involves contact with agents not included here, contact us in order to select the most suitable product.

HARDNESS

Unit of measurement SHORE A in compliance with standard ASTM D 2240 – 64 T. It is only valid if the measurement is made with a thickness of 4 mm. If measurements are made on thinner or thicker samples the figures vary and are invalid, particularly in the case of rubber with low hardness grade.

For sheets with ply inserts, the hardness figures are only indicative.

SPECIFIC WEIGHT

Unit of measurement gr/cm3 representing the weight in kg of sheets with a surface area of 1 square meter and a thickness of 1 mm. It, therefore, determines the volumetric yield of the product, with very important economic implications.

BREAKING LOAD

Unit of measurement kg/cm2 in compliance with standard ASTM D 412 C.

Indicates the force per unit of the surface that will break the rubber.

ULTIMATE ELONGATION

Unit of measurement % (percentage), in compliance with norm ASTM D 412 C.

It indicates the percentage ratio between the length at the moment of breaking and the initial length of the rubber.

TEAR RESISTANCE

Unit of measurement Kg/cm in compliance with norm ASTM D 624 B.

Indicates the force per unit of length that tears or splits the rubber.

RESIDUAL DEFORMATION AFTER COMPRESSION

Unit of measurement % (percentage), in compliance with norm ASTM D 395 B. Indicates permanent residual deformation in relation to the original thickness of the sheets after a technical crushing test at the specific temperature and for a given time.

ABRASION RESISTANCE

Unit of measurement mm3 ABRADED, in compliance with standard DIN 53516. Indicates the degree of resistance of the rubber to abrasion, in cubic millimeters of abraded material from the test sample.

TEMPERATURE RANGE

Unit of measurement °C (degrees centigrade). Indicates the minimum and maximum temperatures that must not be exceeded in the continuous use of the slabs.

BRITTLENESS LIMITS

Unit of measurement °C (degrees centigrade). Indicates the degree of brittleness of sheets. Beyond this temperature, the elastomer breaks very easily and looses all its elastic qualities.

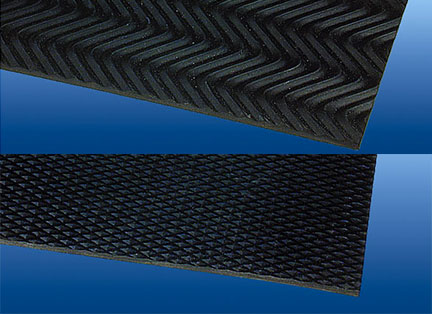

SURFACE TEXTURE

The surface of the sheets can be smooth or impressed with ply.

The impression is achieved with special pliers that produce an even imprint without visible irregularities.

SHEETS AND MAT ROLL FORMATS

The relevant lengths and widths of the rolls are indicated for each type of sheets and matting.

TOLERANCE

HARDNESS

The hardness figures given are valid within a tolerance of ± 5 SHORE A points.

THICKNESSES

Thicknesses have tolerance in compliance with standard ASTM D 1330 – 59 (1965):

Thicknesses up to 1,50 mm ± 0,25 mm

Thicknesses from 1,60 mm to 1,90 mm ± 0,30 mm

Thicknesses from 2,00 mm to 3,90 mm ± 0,40 mm

Thicknesses from 4,00 mm to 20,00 mm ± 0,80 mm

Thicknesses above 20,00 mm ± 1,00 mm